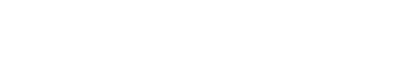

DESIGN DEPARTMENT

A team of expert designers develop and analyse product engineering processes, with the help of cutting-edge 3-D programmes such as Rhinoceros and Matrix. The team works closely with the sampling department.

PROTOTYPING DEPARTMENT

A specialised technical team deals exclusively with the creation of efficient and precise models and samples, always delivering projects within the deadlines, with a particular focus on the specific requests of the individual customer.

WORKSHOP DEPARTMENT

This department is composed of 38 pieces of CNC machinery: lathes, work centres, laser cutters and stamping equipment. This department can process around 50,000 components per week.

CASTING DEPARTMENT

The ancient technique of lost-wax casting for brass, bronze, silver, aluminium and gold, is performed alongside three 3-D printers for creation of prototypes. This department can process around 20,000 components per week.

PRE-SETTING DEPARTMENT

This department is where the stones are pre-set in wax, working closely with the casting department and ensuring exceptional quality of stone positioning following casting. The quality of the final product is far superior than that achieved using glues. This department can pre-set around 100,000 stones per week.

ENAMELLING DEPARTMENT

Our highly-expert and specialised personnel are capable of performing extremely complex enamel work.

GOLDSMITHS' DEPARTMENT

Artisan goldsmiths and masters of the art work every day to polish metals and set stones using ancient, traditional goldsmith’s techniques.

ASSEMBLY DEPARTMENT

Jewellery components are assembled, soldered or glued by specialised personnel. This department is equipped with nine laser soldering units.

GALVANIC DEPARTMENT

Every piece of jewellery undergoes an electroplating process using precious metals, guaranteeing a highly polished finish and lasting quality. We are equipped to guarantee hypo-allergenic and completely nickel-free finishes. The quality of every batch of products is checked using Fischer x-ray fluorescence equipment.

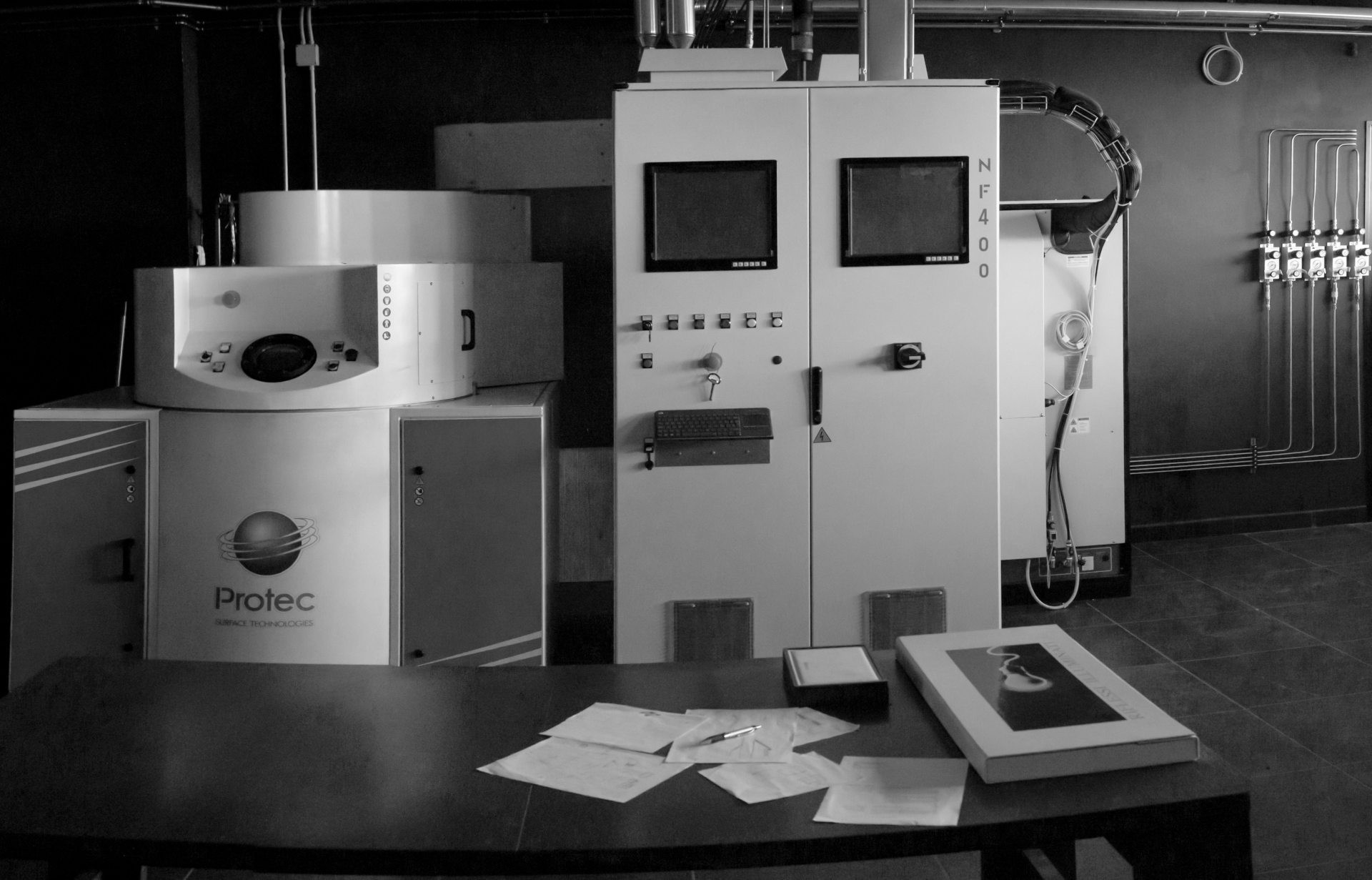

PVD DEPARTMENT

A latest-generation PVD machine completes the range of finishes previously achieved solely using galvanic processes. Decorative application of PVD technology is particularly suitable for innovative, high-quality products that require a very strong surface, resistant to abrasions, sweat, scratches, corrosion, solvents and domestic products. Furthermore, the PVD coating offers a wide variety of shades with lasting quality and colour resistance to UV rays.

It also boasts hypo-allergenic qualities, in compliance with applicable legislation, and minimal environmental impact, making PVD technology completely green and eco-sustainable.

QUALITY CONTROL

In this department, our operators ensure that every product complies with requirements, performing all the necessary checks and rejecting any items that do not meet quality standards.

LOGISTICS DEPARTMENT

The logistics department manages and processes packaging and shipping activity. Material is carefully packaged following customer requirements, with the option of a specialised packaging service using materials provided directly by the customer.